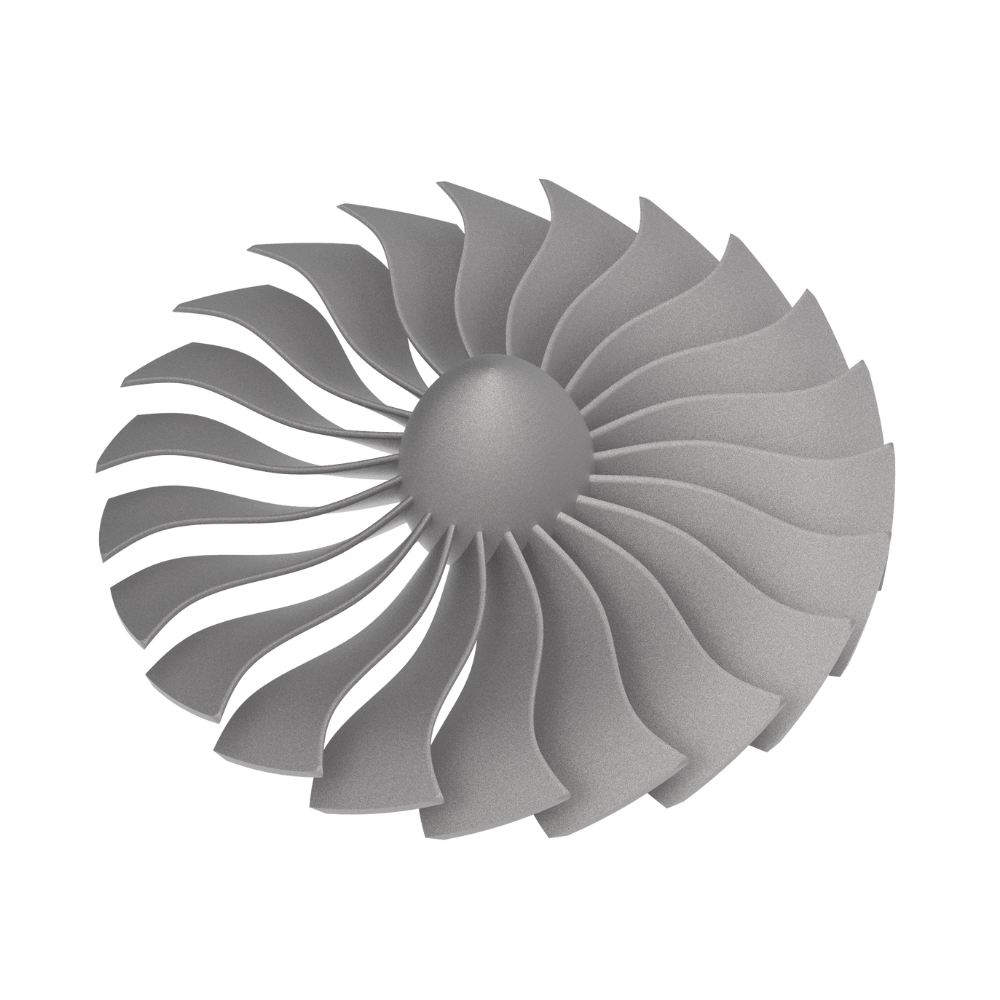

HBD TC4 Titanium Alloy

Lightweight, High-Strength Titanium Alloy

HBD TC4 titanium alloy (Ti6Al4V) is an α+β type alloy known for its high strength, excellent mechanical properties, and corrosion resistance. With a lower density than other metals and a long-term use temperature of up to 400 °C, it is widely used in industries requiring lightweight, durable material.