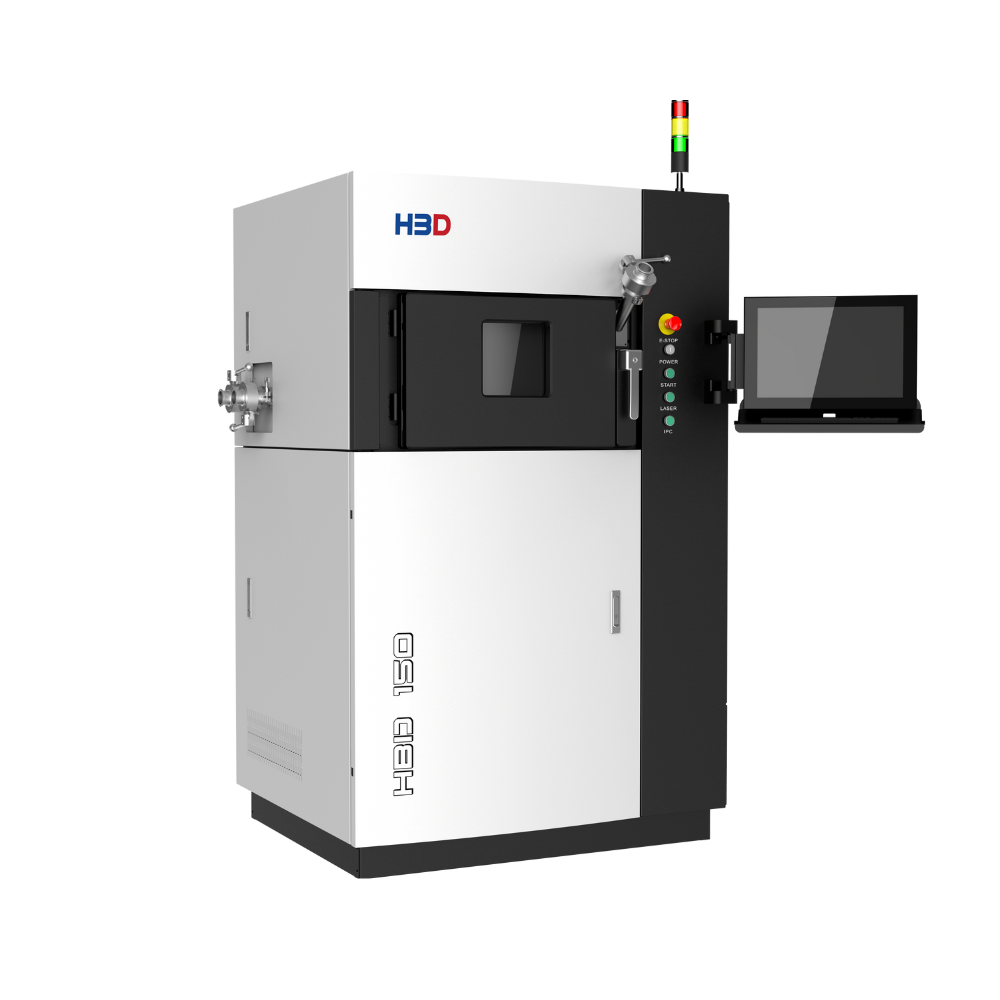

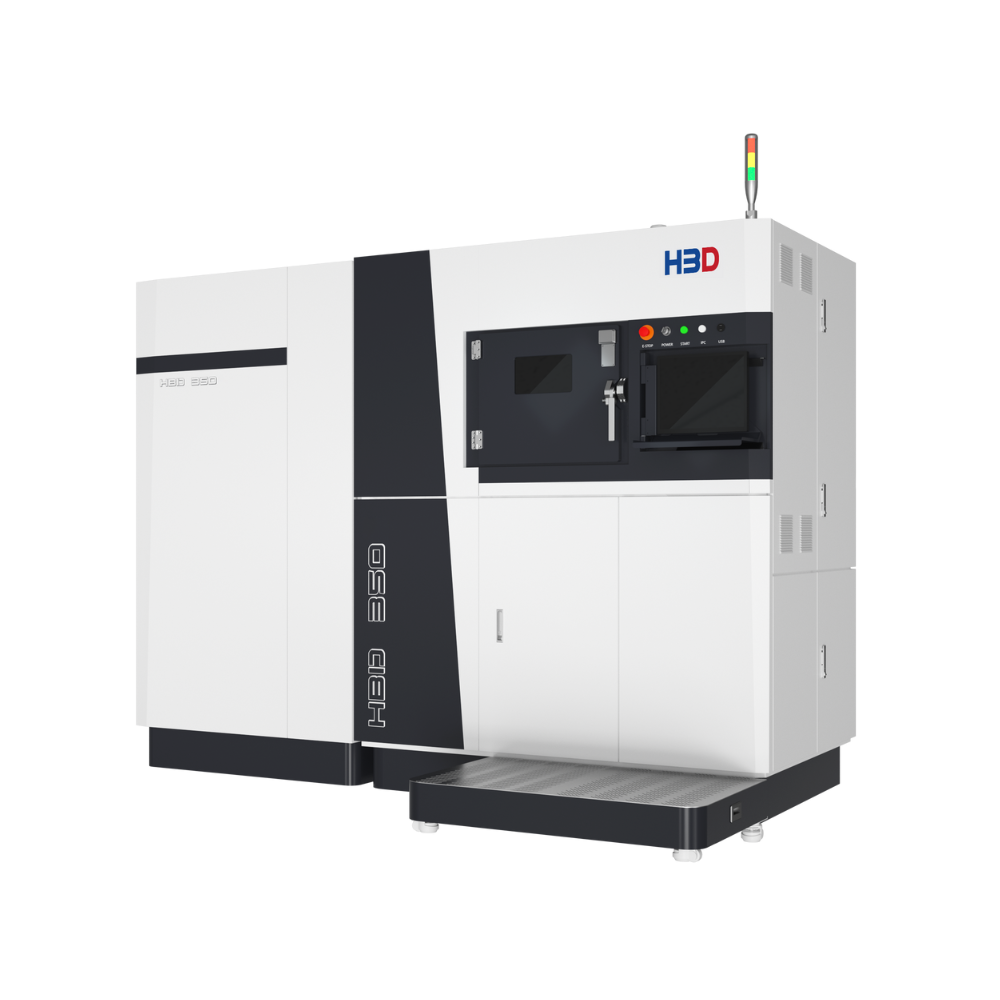

HBD 350

Versatile Metal 3D Printer

Quality meets efficiency in the HBD 350, which supports both dual and quadruple laser configurations and offers a mainstream build plate size. It provides a stable powder supply, efficient recoating, and closed automatic powder circulation.

Complementary Equipment and Accessories

Based on your request, the solution package includes the following:

Explosion-Proof Cleaner, Nitrogen Generator, Multi-Purpose Forklift, Powder Drying Oven, Powder Suction Machine, Powder Sieving Machine, Wire-Cutting EDM Machine, Vacuum-Atmosphere Heat Treatment Furnace, Sandblasting Station

Materials: HBD series metal 3D printers are offered with parameters customized for the metal powder of your choice.

LPBF (Laser Powder Bed Fusion)

Metal Powders (Metals)

Product Specifications

Download the technical datasheet for HBD 350 metal 3D printer.

Download DatasheetLPBF (Laser Powder Bed Fusion)—also known as SLM (Selective Laser Melting)

325 × 325 x 400 mm

2 x 500 W (Standard), 2 x 500 W (IPG), 4 x 500 W (Standard)

±0.05-0.20 mm

20-120 μm

70-200 μm

≤10,000 mm/s

≤100 ppm

Fully sealed system with automatic oxygen content monitoring, powder recycling, cleaning, and collection efficiency of ≥99%.

≥99.90%

Yes

Yes

Yes

500 W Laser: AC 380 V, 50/60 Hz, Maximum: ≤14.0-15.0 kW, Average: ≤5.5-7.0 kW

1000 W Laser: AC 380 V, 50/60 Hz, Maximum: ≤15.0-17.0 kW, Average: ≤7.0-9.0 kW

1,900 mm × 1,500 mm × 2,300 mm

3,000 kg

Yes

HBD is recognized globally for developing and manufacturing LPBF systems, with over 200 patents, prestigious certifications, and over 15 years of experience, having served 1000+ businesses in over 25 countries. This expertise and application know-how allow for better customer service, enabling the development of custom and cost-effective solutions for businesses in a variety of industries.

The research center of HBD hosts over 50 industrial metal additive manufacturing systems, all dedicated to application development and creating optimized parameters for third-party materials, testing hundreds of materials each month. This ensures maximized compatibility with third-party materials, allowing customers to achieve success with their applications using the materials suitable for them.

HBD systems offer a monitored manufacturing process. The integral sealed, automatic monitoring of oxygen content, and recycling with a cleaning and collection coefficient over 99% coupled with a closed-loop system, allow for stable and repeatable outcomes. The result is a printing system that can operate continuously for extended periods, delivering reliable production performance.

HBD is recognized globally for developing and manufacturing LPBF systems, with over 200 patents, prestigious certifications, and over 15 years of experience, having served 1000+ businesses in over 25 countries. This expertise and application know-how allow for better customer service, enabling the development of custom and cost-effective solutions for businesses in a variety of industries.

The research center of HBD hosts over 50 industrial metal additive manufacturing systems, all dedicated to application development and creating optimized parameters for third-party materials, testing hundreds of materials each month. This ensures maximized compatibility with third-party materials, allowing customers to achieve success with their applications using the materials suitable for them.

HBD systems offer a monitored manufacturing process. The integral sealed, automatic monitoring of oxygen content, and recycling with a cleaning and collection coefficient over 99% coupled with a closed-loop system, allow for stable and repeatable outcomes. The result is a printing system that can operate continuously for extended periods, delivering reliable production performance.

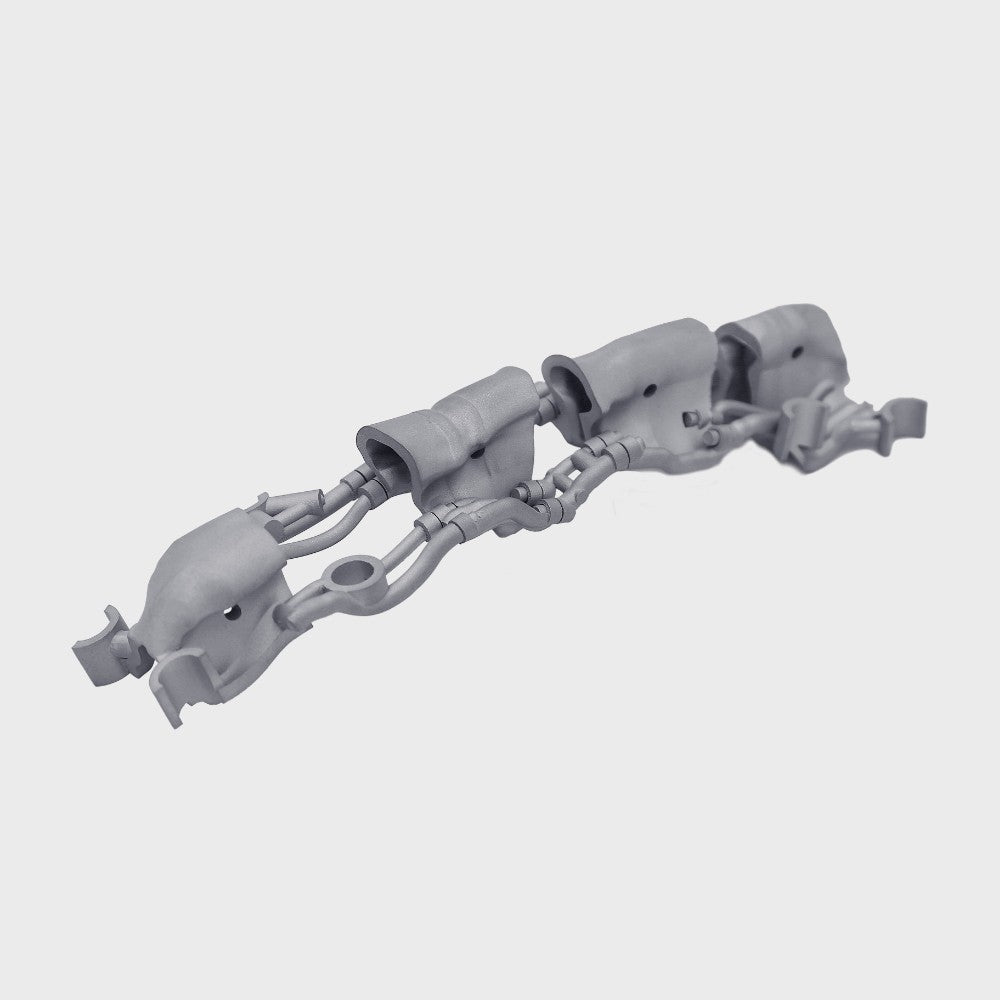

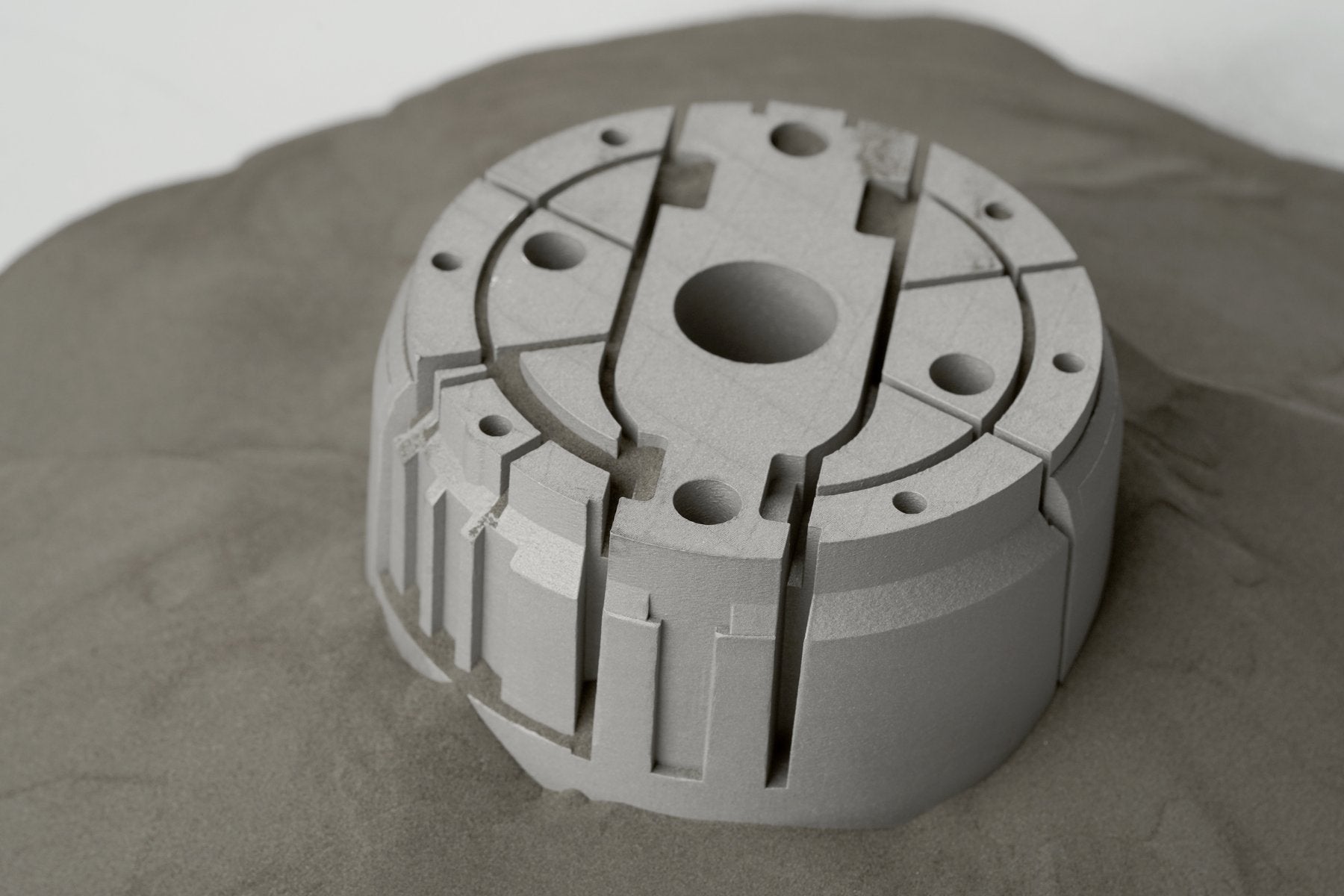

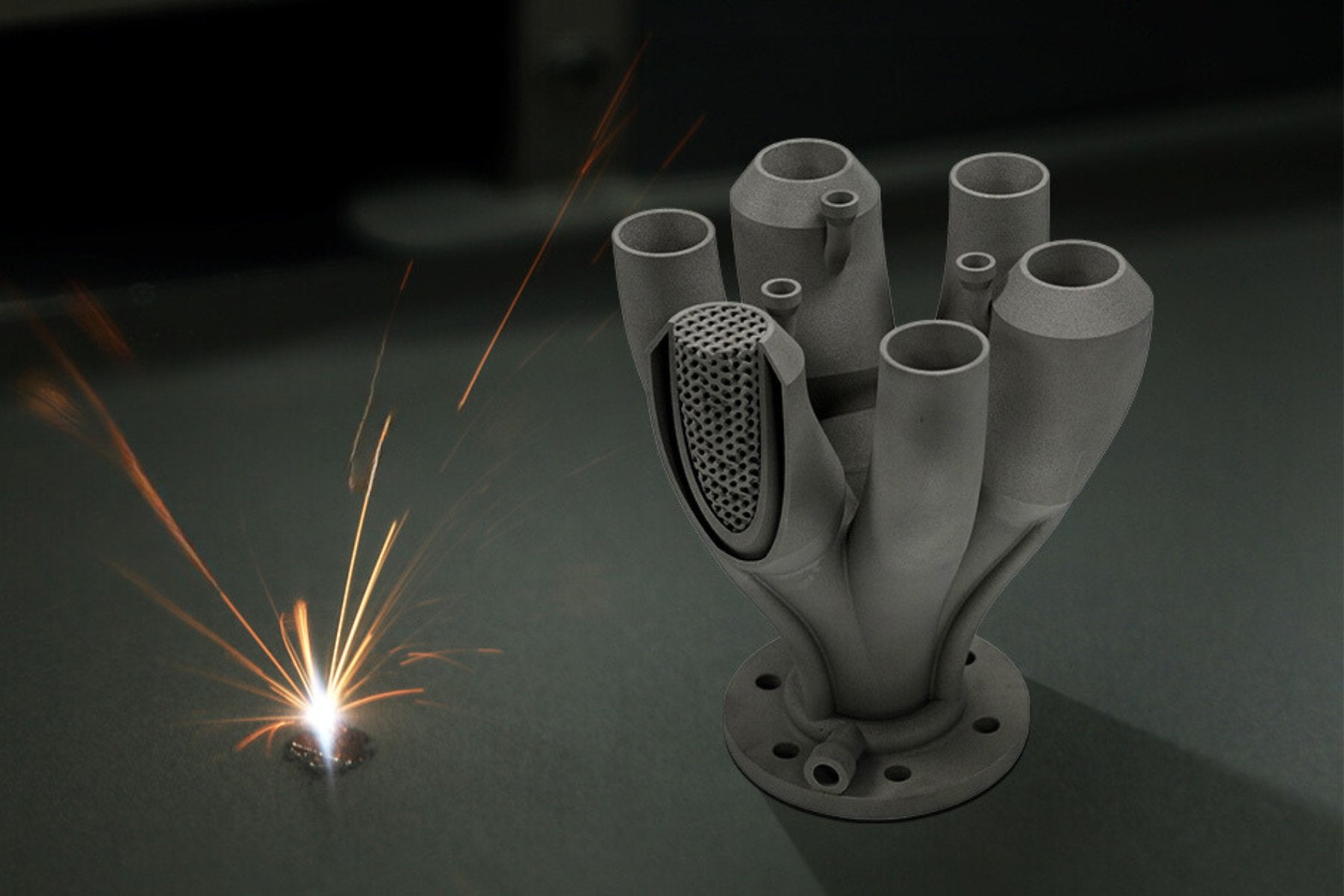

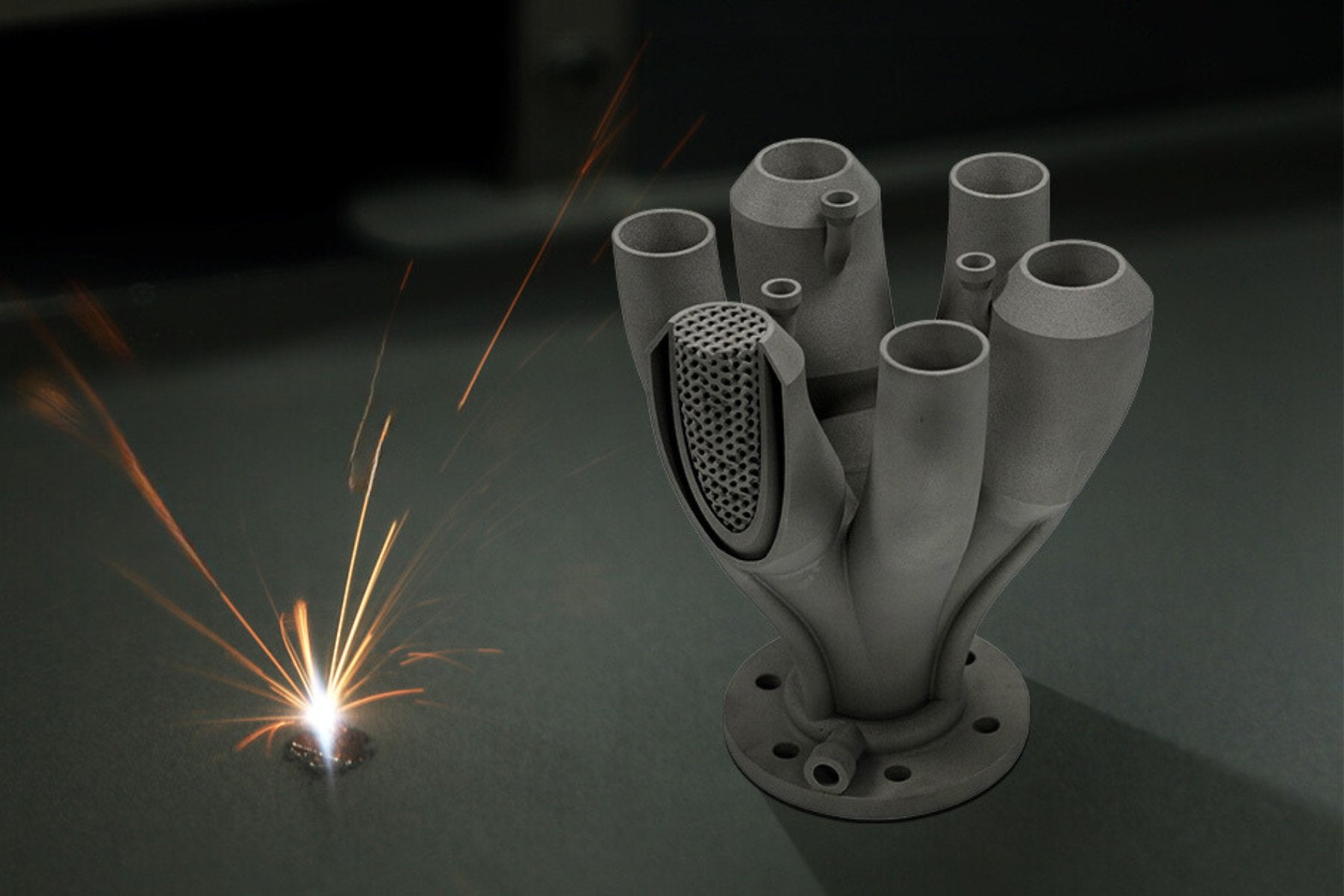

Disruptive Applications

The layer-by-layer fabrication of parts allow for the creation of parts with complex geometries that would be difficult or impossible to produce with casting or machining.

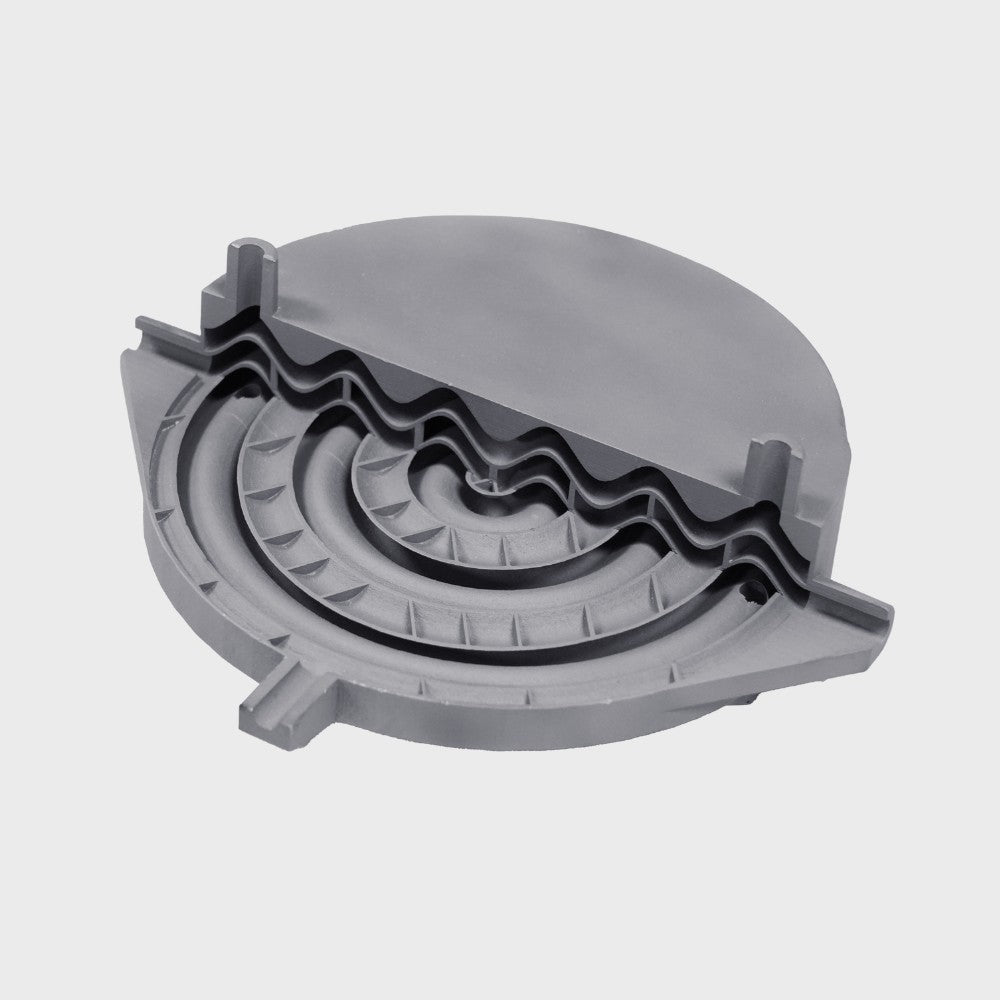

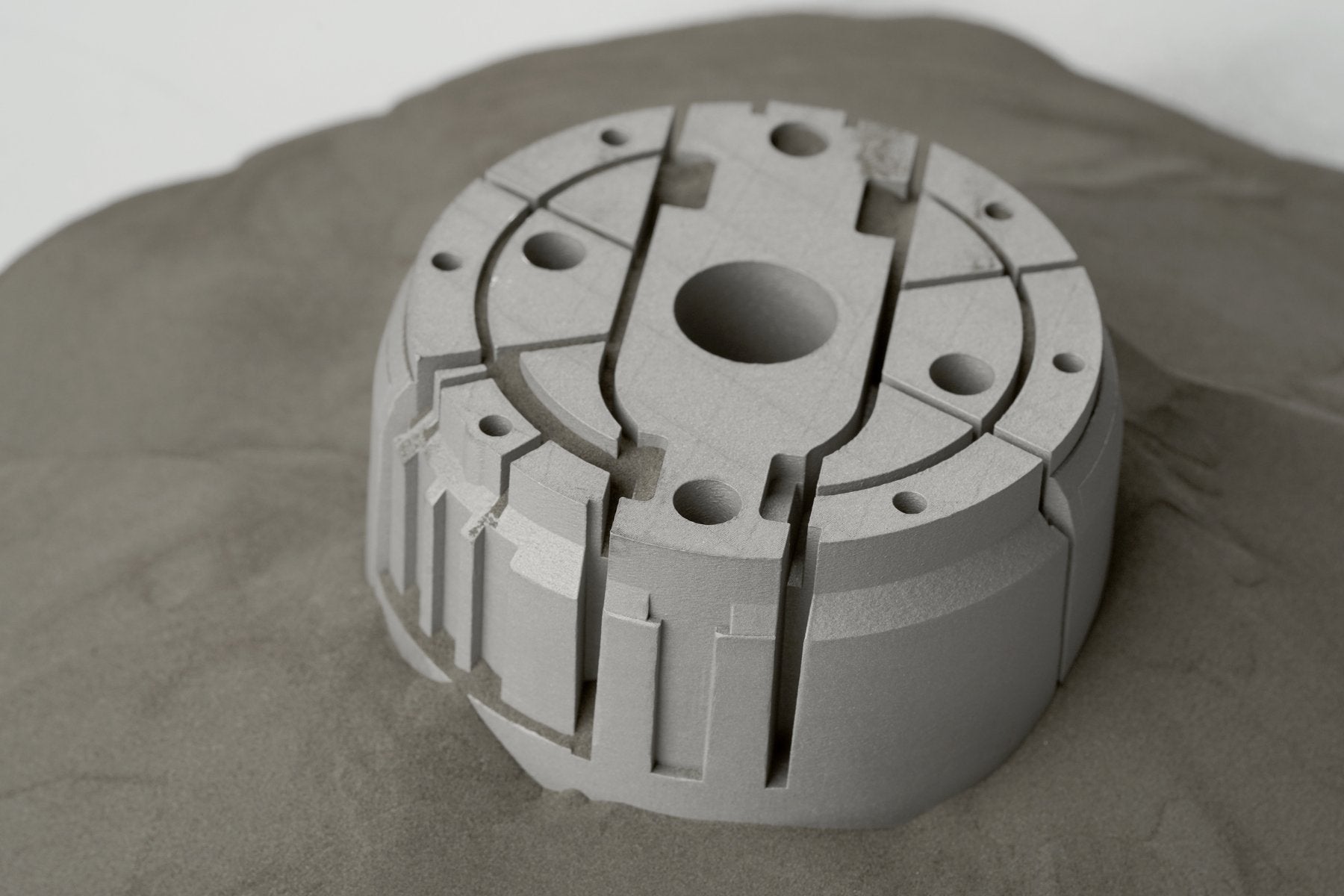

Hydraulic Manifold

Metal additive manufacturing allows for the consolidation of multiple parts into a single, complex hydraulic manifold, enhancing flow characteristics while reducing size, weight, and assembly time.

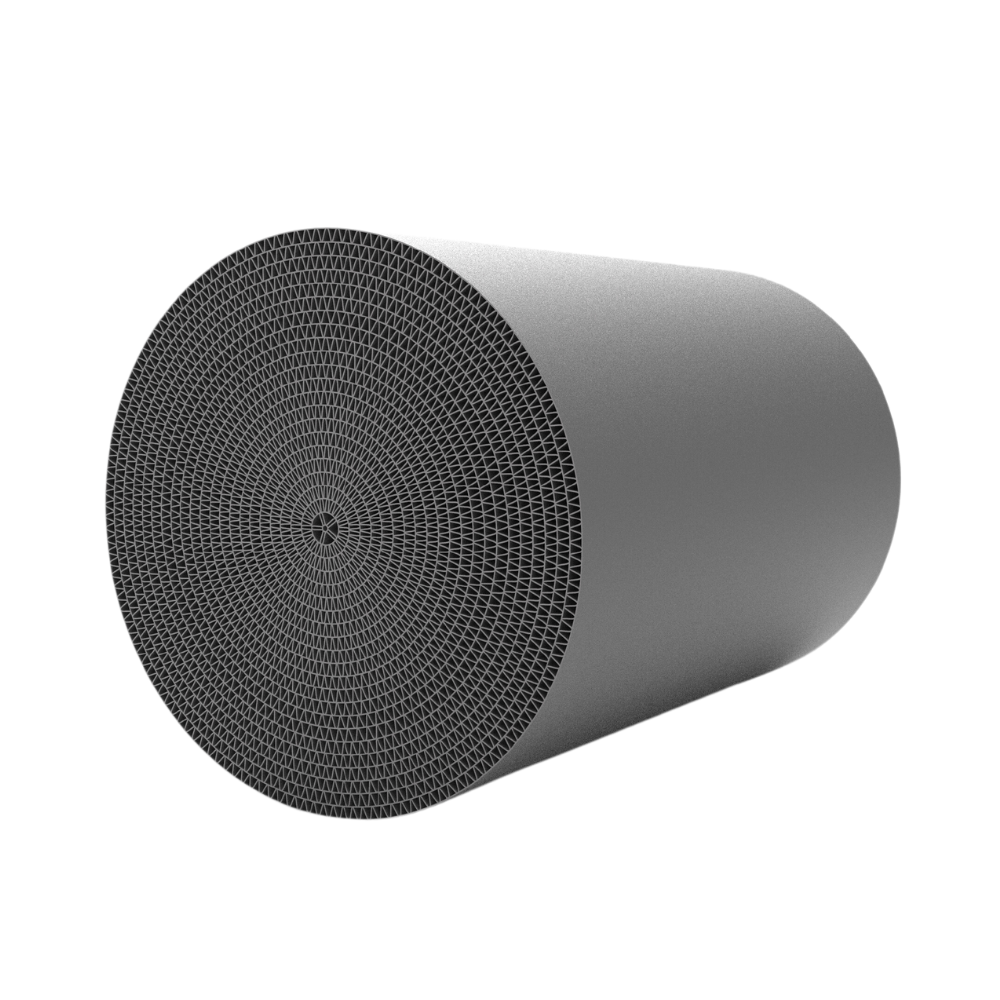

Conformal Cooling

In the production of molds and inserts, metal AM enables the integration of conformal cooling channels that closely follow the contours of the mold cavity, resulting in more uniform cooling, reduced cycle times, and consistently higher quality in final products.

Heat Exchanger

Maximizing the surface area is essential for heat exchanger efficiency, and metal AM supports this by allowing the creation of highly-complex internal geometries that significantly increase the surface area, thereby enhancing heat transfer capabilities.

Trusted by

Driving Innovation

LPBF uses lasers to fully melt each layer into the previous one, resulting in completely dense, end-use quality metal parts. CAD files are converted into individual vectors that the laser follows during each layer's exposure, providing businesses with the power of design freedom.

HBD 350

Feature Highlights

HBD 350 supports configurations with dual and quadruple lasers, featuring an efficient and stable powder supply and recoating system. It also offers a closed, automatic powder circulation system and an independent long-term multi-stage purification system.

Customizable Parameters

Customizable parameters and a vast library of proven parameters for third-party materials provided by HBD mean a manufacturing solution that adapts to your business's needs.

System Stability

HBD 350's sub-vacuum sealed chamber, closed-loop air circulation, and high-speed deoxygenation system ensure utmost precision and safety.

Pressure sensors, oxygen detection, and comprehensive safety measures guarantee stable and secure operation. The innovative powder recycler optimizes material usage.

High-Speed Production

Bidirectional recoating, dual and quadruple laser configurations, and scanning speeds of 10,000 mm/s allow for the rapid production of complex parts in days.

High-Precision Parts

Customizable for standard and IPG lasers of various powers, HBD 3D printers offer dimensional accuracy down to ±0.05 mm for intricate applications.

Bidirectional Recoating

Bidirectional recoating in LPBF printers streamlines the application of new powder layers by allowing the recoater to spread powder in both directions, reducing the overall build time and enhancing the efficiency of the printing process.

This not only speeds up production but also minimizes disruptions to the powder bed, leading to smoother surfaces and more consistent part quality.

Full-Field Laser Overlap

HBD 350's full-field laser overlap ensures uniform laser coverage across the build plate, enhancing material consistency and mechanical properties while reducing porosity and defects.

This feature optimizes material usage and speeds up production, making it essential for high-performance industries like aerospace and automotive.

Independent Atmospheric Purification System

Equipped with an efficient and secure independent atmospheric purification system to ensure highly efficient purification during the printing process, providing a safe and stable solution for printing reactive metals.

It also features an automatic closed-loop purification circulation system with advanced dust removal and secondary filtration. These enhancements ensure high filtration efficiency, meeting H13 standards.

Sealed Operating Environment

Adopting a sealed glove structure, a sealed chamber is reserved for the powder adding and suction interface, which can be operated without opening the chamber for powder adding and powder clearing.

Long-Lasting Filtration

Upgradeable configuration featuring a self-cleaning, long-lasting filtration system with a lifespan exceeding 5 years, ideal for extended batch printing operations.

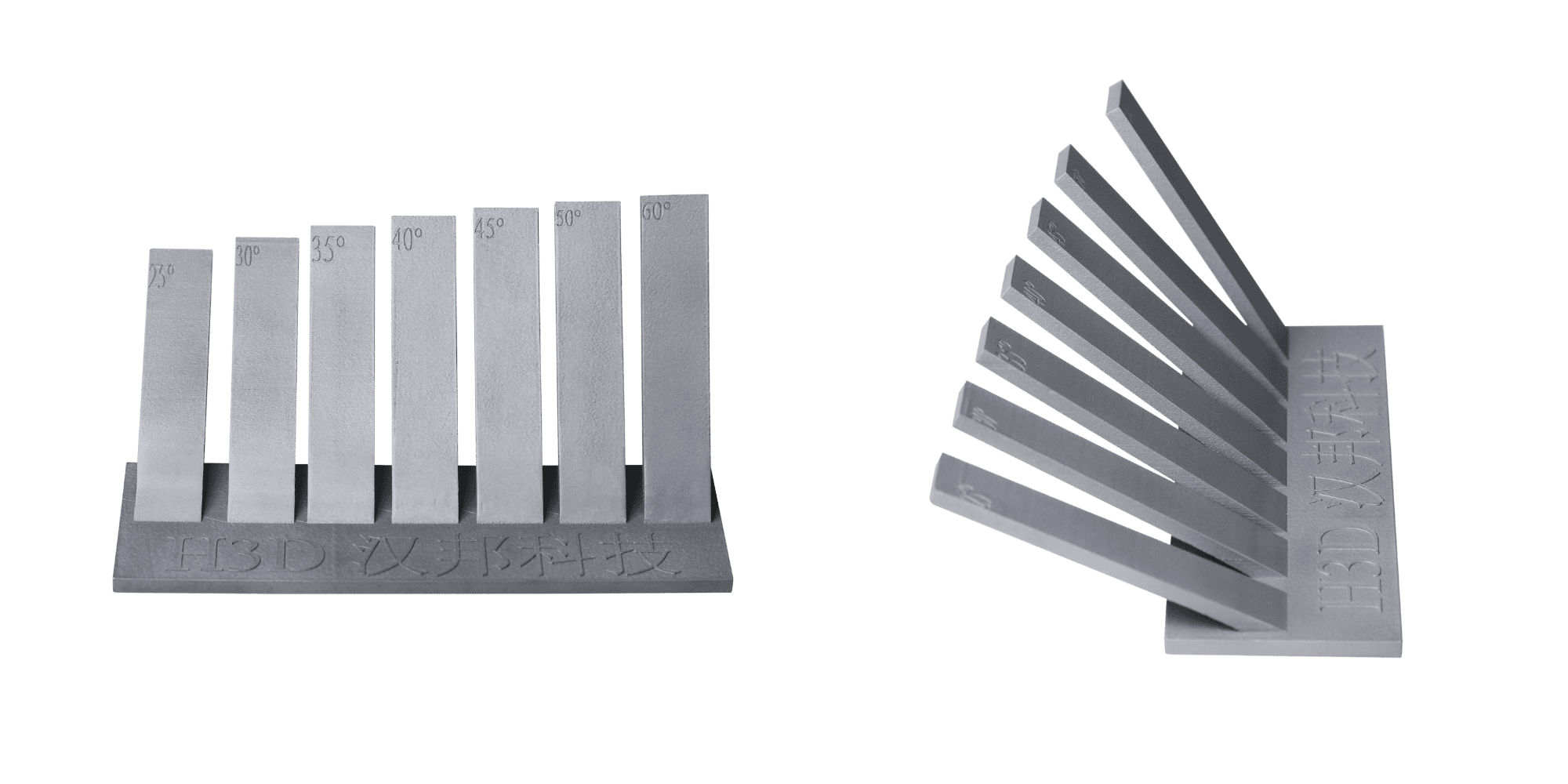

No-Support 3D Printing

Typically, support structures are necessary in LPBF processes to prevent the deformation of parts due to high temperatures and to anchor the build to the substrate.

However, no-support LPBF printing can offer several distinct advantages, such as material efficiency, reduced post-processing, and faster build times.

Application Experience

HBD's research center constantly works on process and application development for no-support 3D printing, achieving successful prints with support angles below 45°.

Common Applications

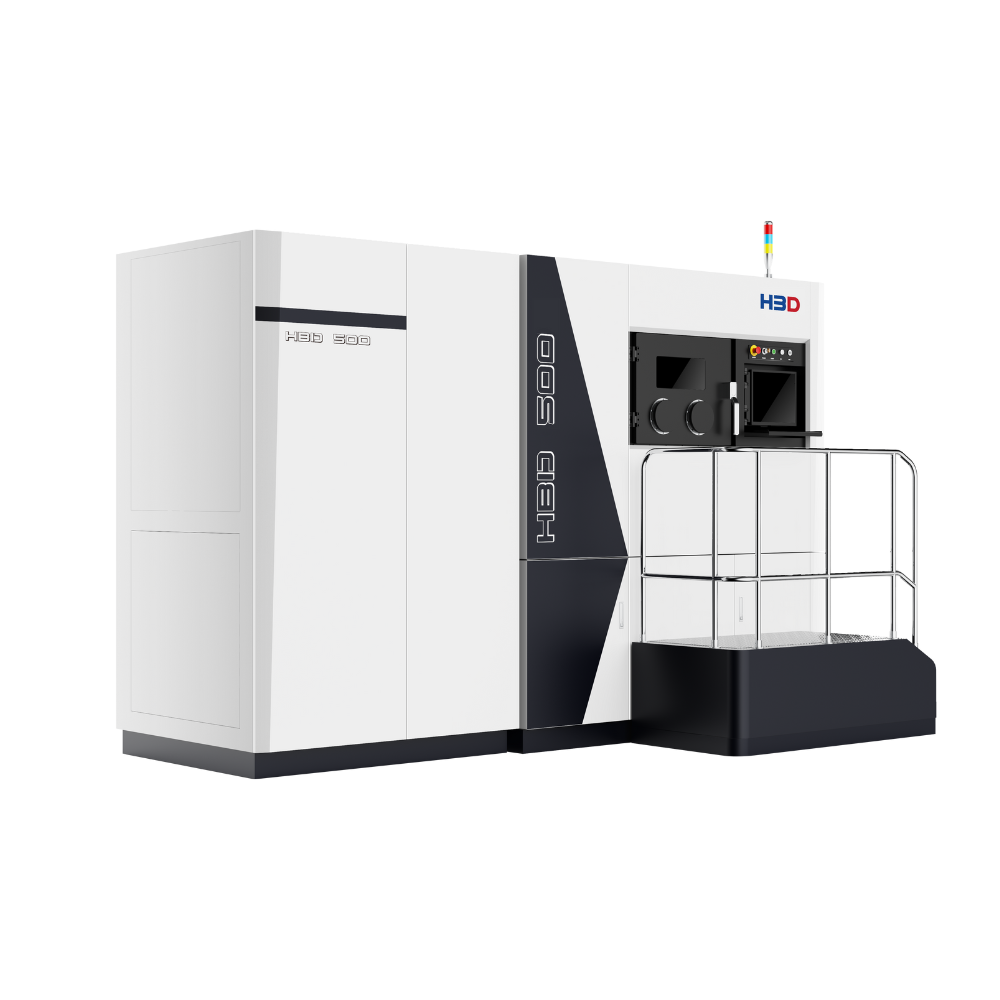

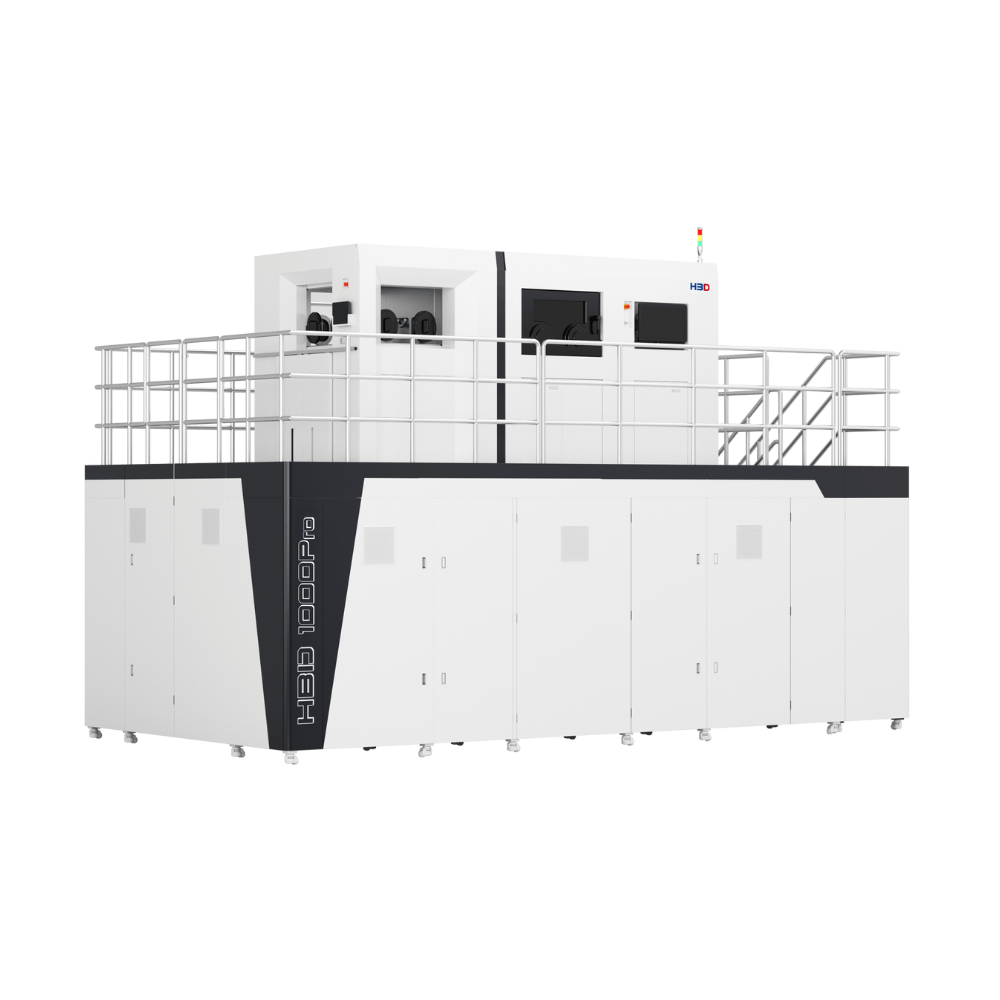

HBD Series

Compare with similar 3D printers.

Each HBD 3B printer offers distinct build plate sizes and laser configurations tailored to your specific part sizes, materials, and production volumes. Contact us to choose the model that best suits your business needs.

Request a Quote265 × 175 x 120 mm

325 x 325 x 400 mm

350 x 400 x 400 mm

2 x 300 W (Standard), 2 x 500 W (Standard)

2 x 500 W (Standard), 2 x 500 W (IPG), 4 x 500 W (Standard)

2 x 500 W (IPG), 6 x 500 W (Standard), 6 x 1000 W (IPG)

±0.05-0.10 mm

±0.05-0.10 mm

±0.05-0.20 mm

10-40 μm

20-120 μm

20-120 μm

40-80 μm

70-200 μm

70-200 μm

Compatible Materials

HBD metal 3D printers are open-material systems and compatible with an extensive catalog of third-party metal powders, ranging from stainless steels to titanium-based alloys, and tool steels. This section only lists the compatible metal powders customized by HBD.

Stainless Steels

HBD 316L Stainless Steel, HBD 17-4 PH Stainless Steel, HBD 15-5 PH Stainless Steel

Tool Steels

HBD 420 Tool Steel, HBD CX Tool Steel

Aluminum-Based Alloys

HBD AlSi10Mg Aluminum Alloy

Titanium-Based Alloys

HBD TC4 Titanium Alloy, HBD TA15 Titanium Alloy

Cobalt-Based Alloys

HBD CoCrMo Cobalt Alloy

Maraging Steels

HBD 18Ni300 Maraging Steel

Copper-Based Alloys

HBD CuCrZr Copper Alloy

Tungsten

HBD W Tungsten

Superalloys

HBD IN625 Superalloy, HBD IN718 Superalloy, HBD GH99 Superalloy, HBD GH230 Superalloy, HBD Hastelloy X Superalloy

Links and Documents

Check out HBD's relevant resources for LPBF printers.

Links and Documents

Check out HBD's relevant resources for LPBF printers.