Investment Casting with SLA 3D-Printed Patterns

How does it work?

With 3D-printed stereolithography patterns, you can enhance your designs and achieve greater complexity. Unlock new possibilities while simplifying your manufacturing process and lowering production costs.

Investment Casting with UnionTech in 9 Steps

Step 1

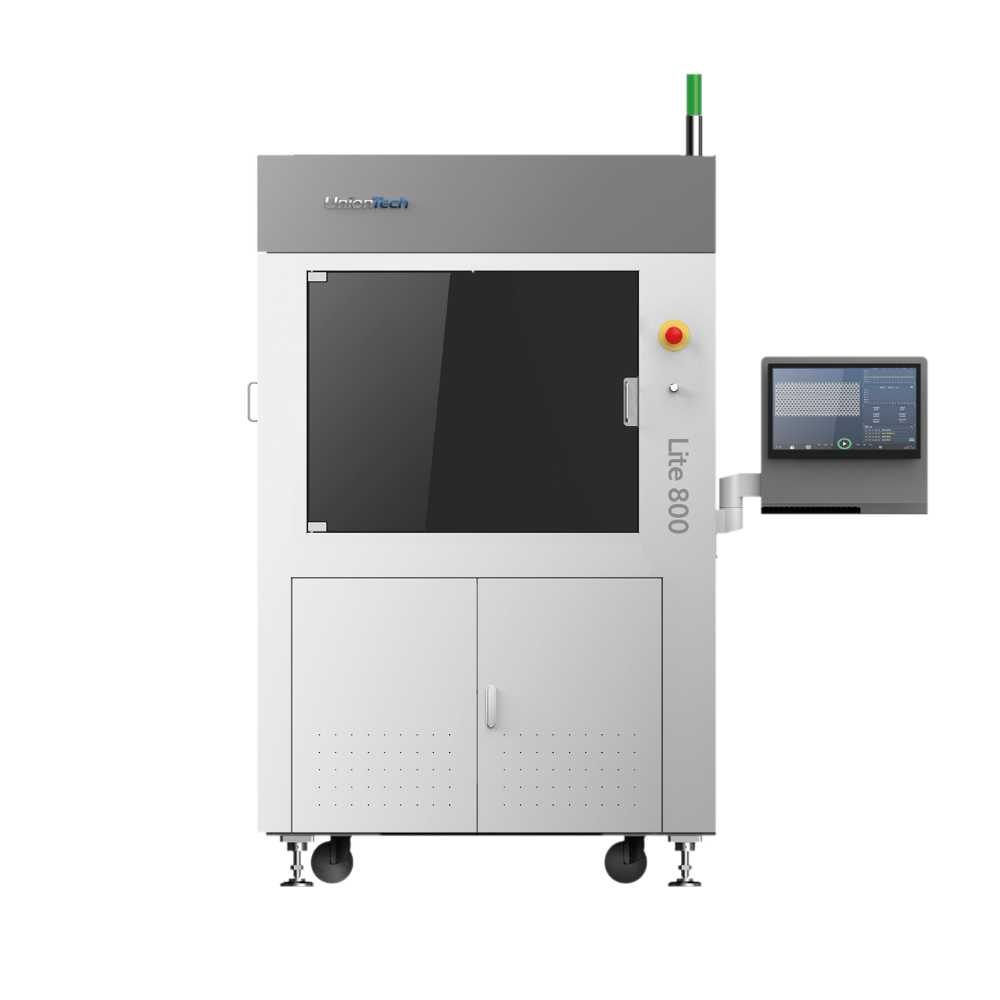

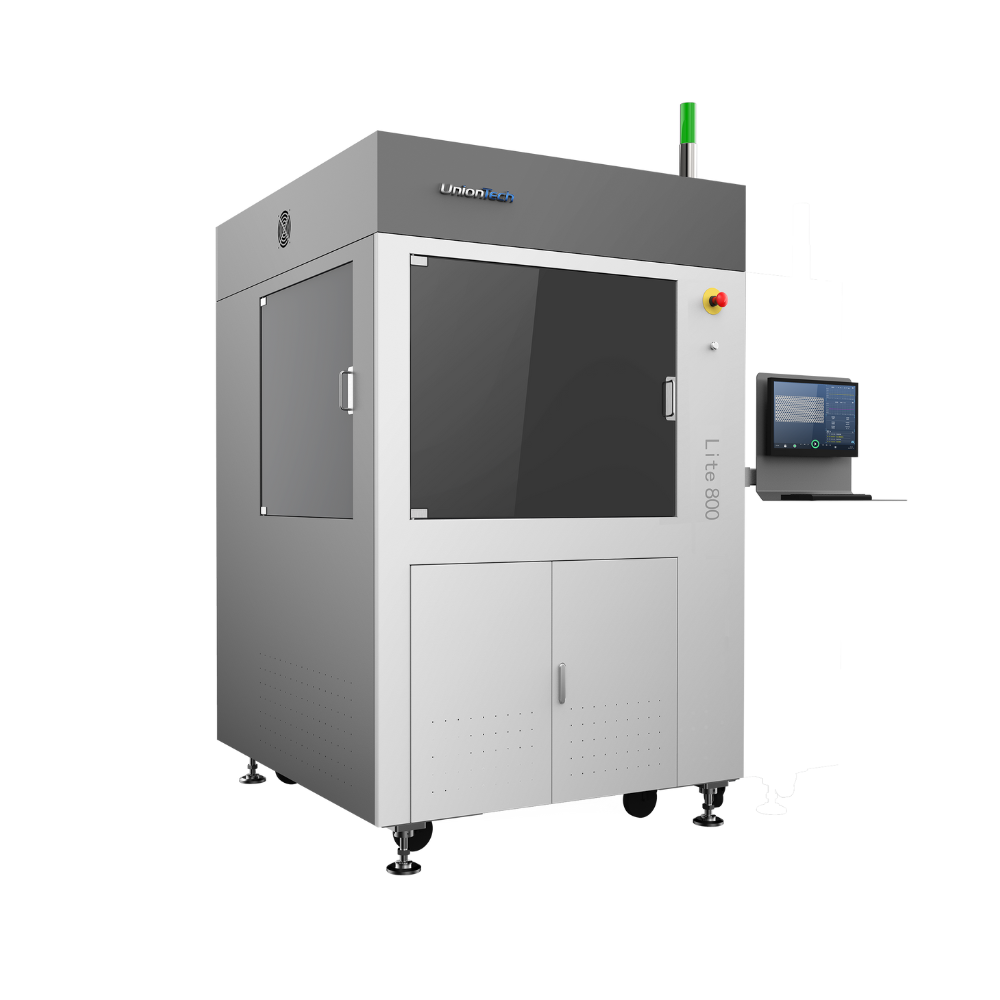

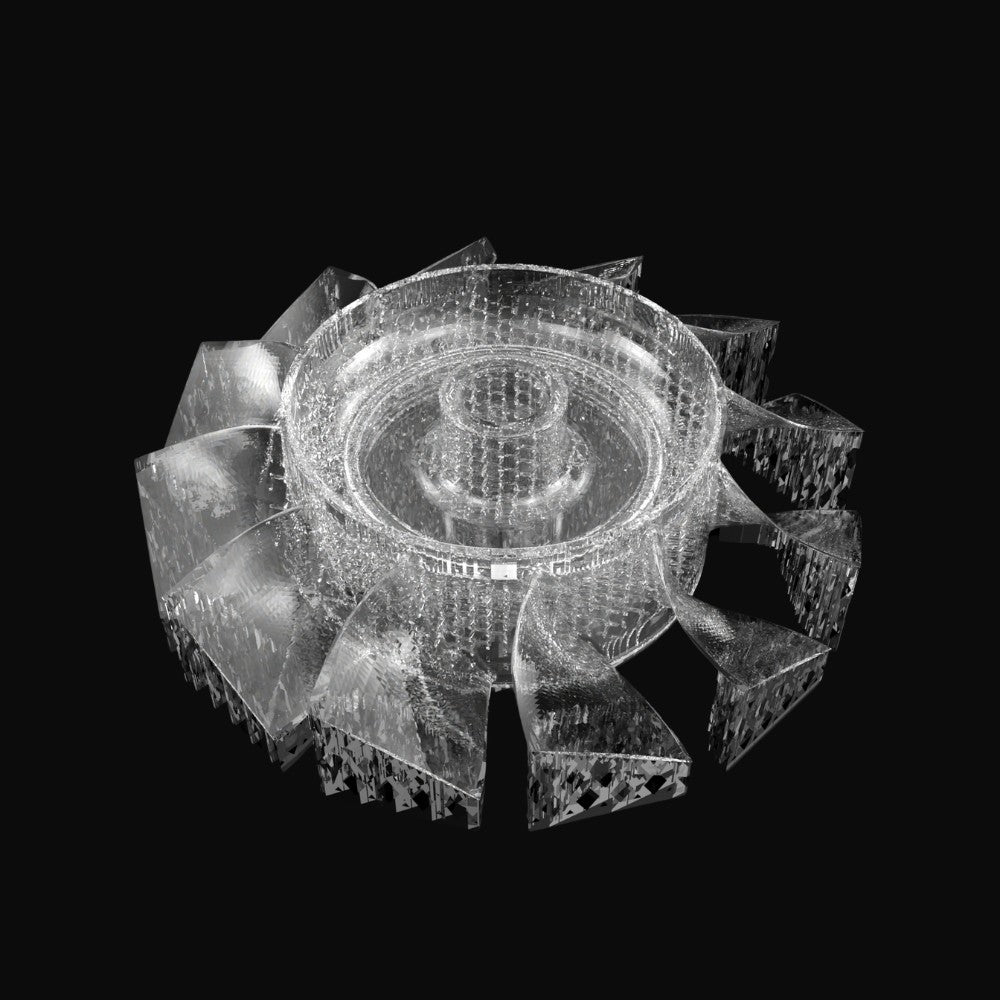

3D Printing

Create master patterns for investment casting using UnionTech's industrial SLA 3D printers.

Step 2

Wax Tree

Assemble the printed patterns into a wax tree to prepare multiple casts simultaneously.

Step 3

Ceramic Slurry

Coat the mold with layers of ceramic slurry to form a hard shell around the 3D-printed pattern.

Step 4

Dewaxing

Burn and remove the pattern using an industrial furnace, leaving a hollow cavity in the ceramic shell.

Step 5

Ash Cleaning

Clean out any residual ash or debris from the hollowed-out cast.

Step 6

Metal Casting

Pour molten metal into the hollow cavity, forming the final metal part.

Step 7

Deshelling

Remove the cast metal from the ceramic shell to reveal the rough metal component.

Step 8

Post-Processing

Refine the cast parts through techniques like cutting, polishing, sandblasting, and machining.

Step 9

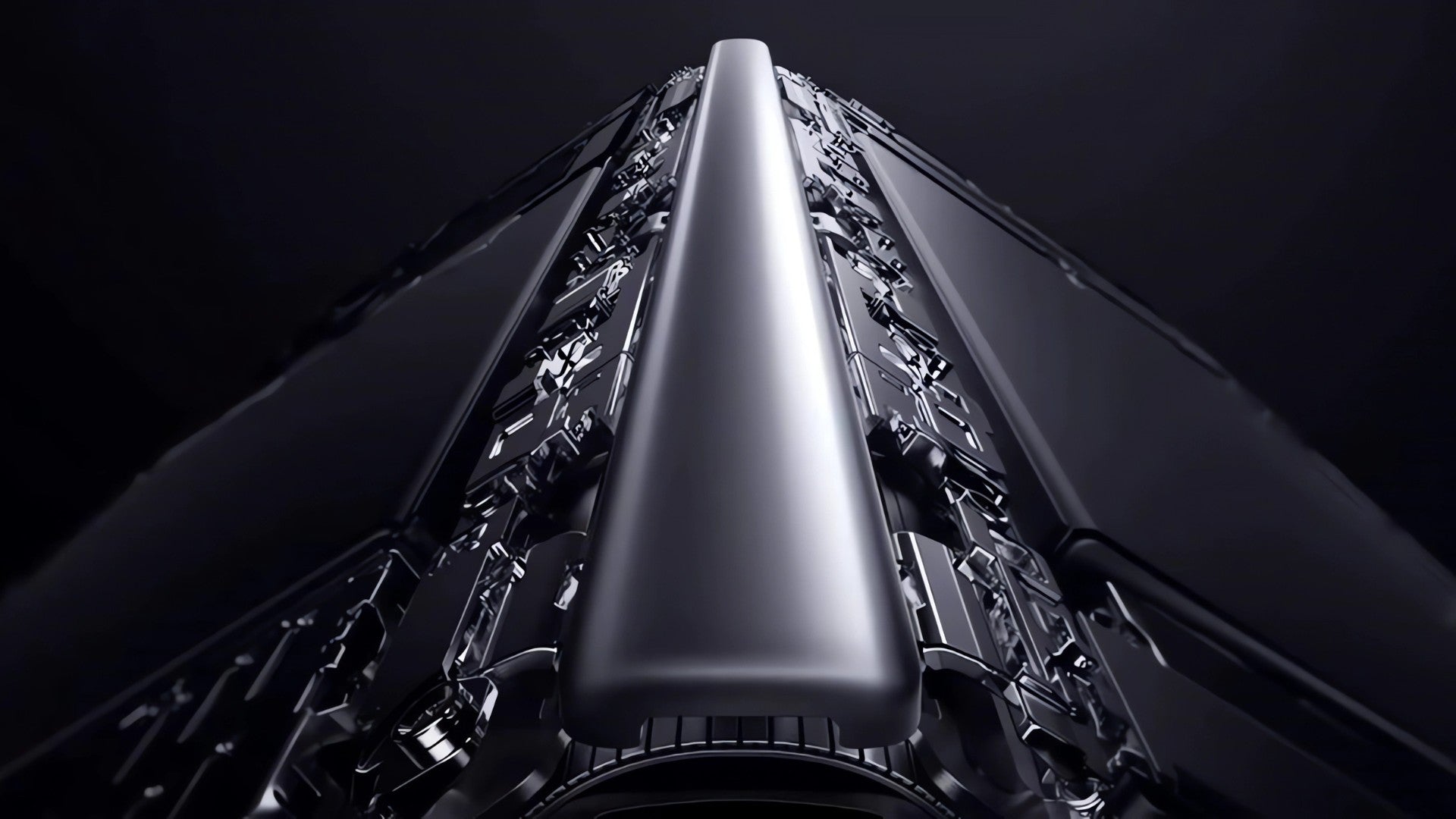

Finished Parts

Assemble the final parts after the quality control processes.

Advantages

Why choose SLA 3D printing?

Manufacturers are shifting away from traditional methods of creating investment casting patterns, such as CNC-machining molds and injecting wax, in favor of the design flexibility and cost efficiency offered by directly 3D printing master patterns for casting.

Go from CAD data to final part without molding or wax injection.

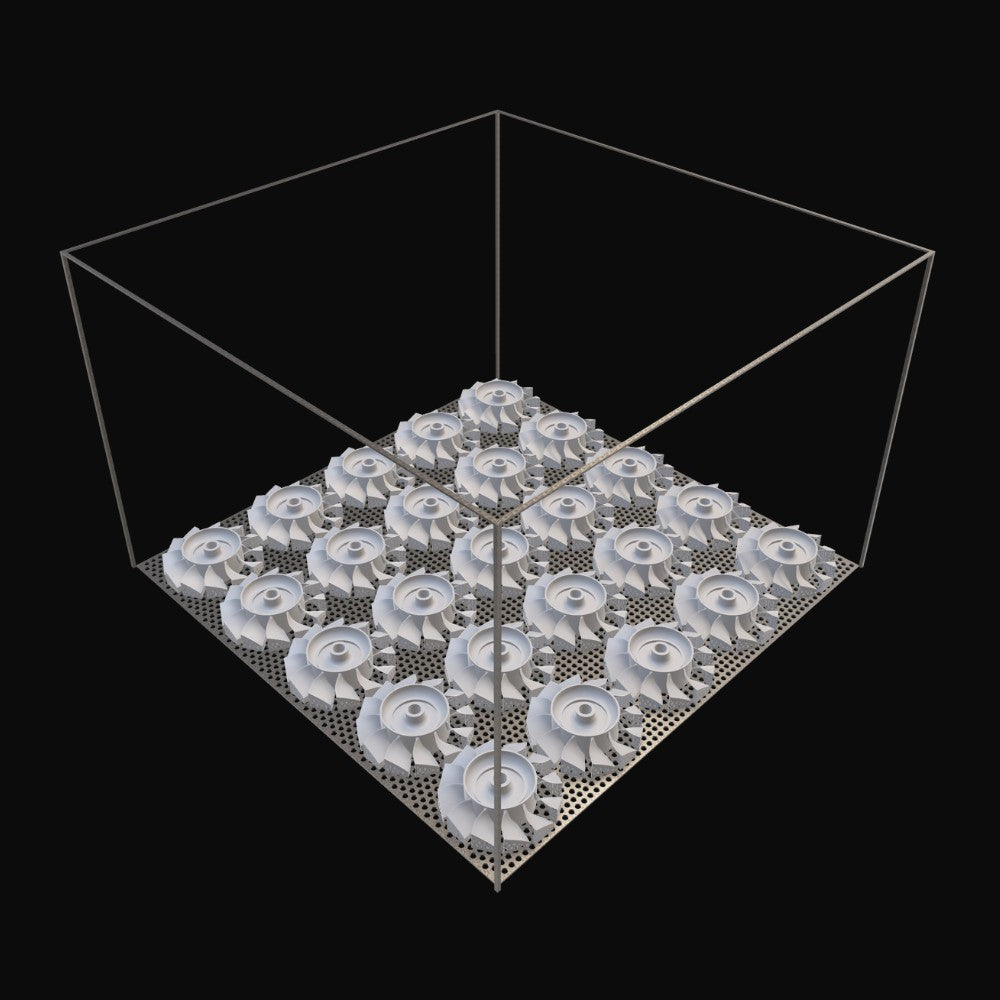

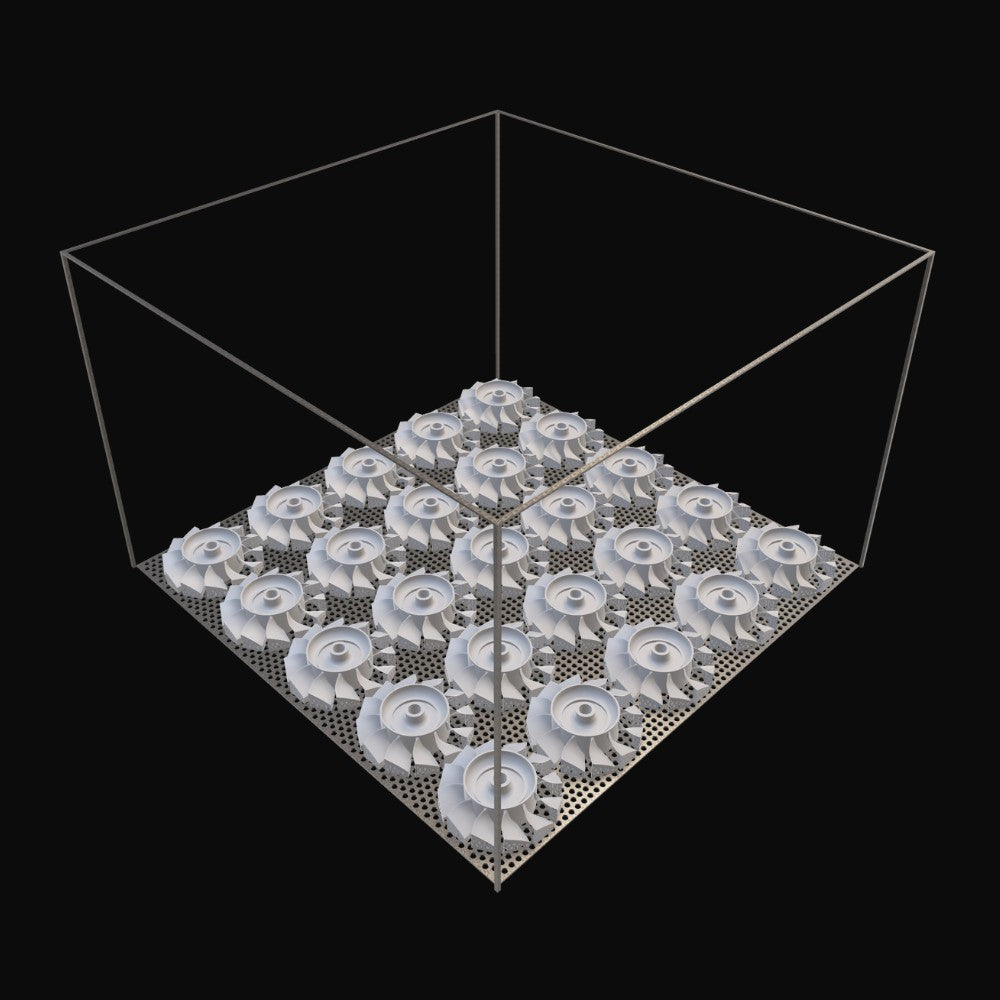

25 different models for investment casting patterns can be 3D printed with UnionTech Lite800, all ready for casting, in the same day. The part size is 150.00 x 150.00 x 38.40 mm. Polydevs software was used for data preparation.

Go from CAD data to final part without molding or wax injection.

25 different models for investment casting patterns can be 3D printed with UnionTech Lite800, all ready for casting, in the same day. The part size is 150.00 x 150.00 x 38.40 mm. Polydevs software was used for data preparation.

SLA 3D Printing

1-2 Days

Rubber/Silicone Molds

7-10 Days

CNC-Machined Molds

2-3 Weeks

UnionTech 3D Printers

UnionTech enables cost-effective and rapid manufacturing of investment casting patterns using materials like Somos® WaterShed XC 11122 and Crysta-EB, providing businesses with a competitive advantage. Want to learn more about this application? Contact us today.

Contact UsBlog Posts

Creating Investment Casting Patterns with SLA 3D Printing

UnionTech's industrial SLA 3D printers revolutionize investment casting by delivering precise, complex patterns more efficiently than traditional methods. These advanced 3D printed patterns signifi...

Foldable Smartphones: The Role of 3D Printing

HONOR's the Magic V2 foldable smartphone was unveiled on July 12th, 2023, by CEO Zhao Ming. This device sets a new standard for foldable smartphones with its ultra-thin profile of just 9.90 mm when...