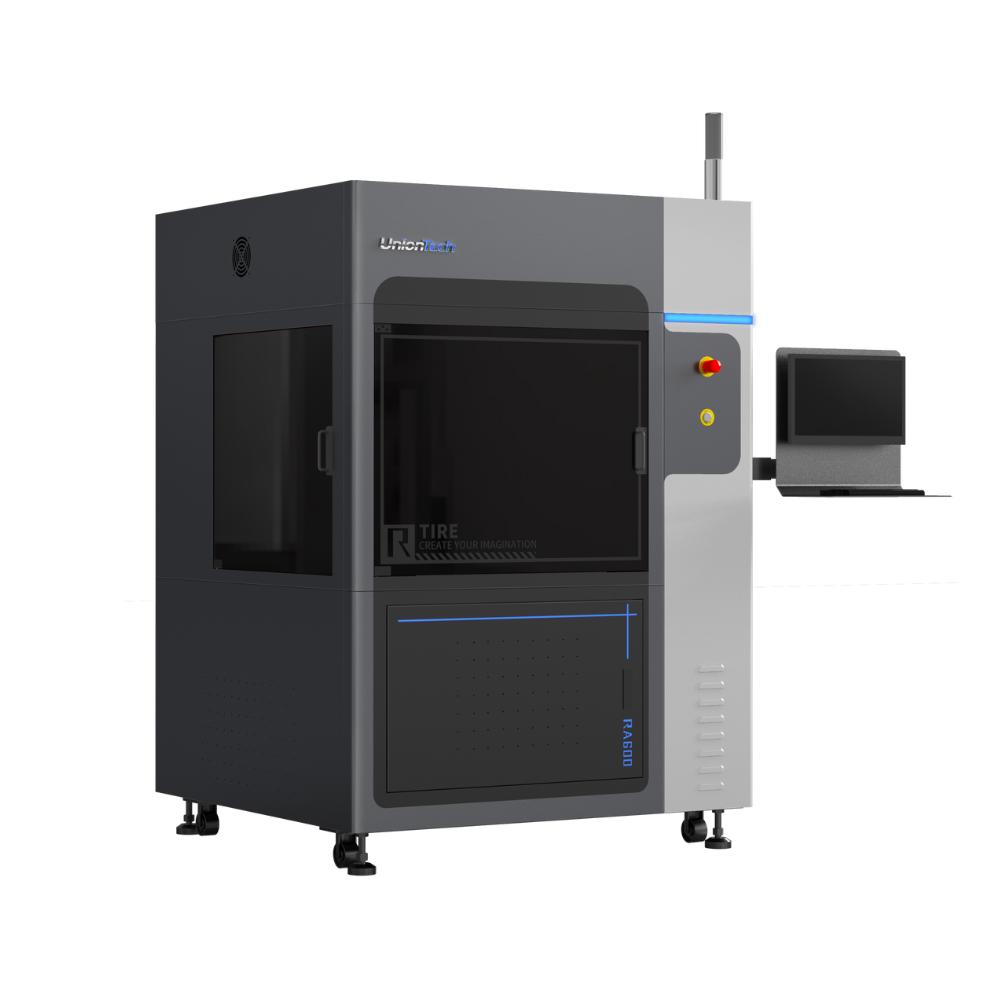

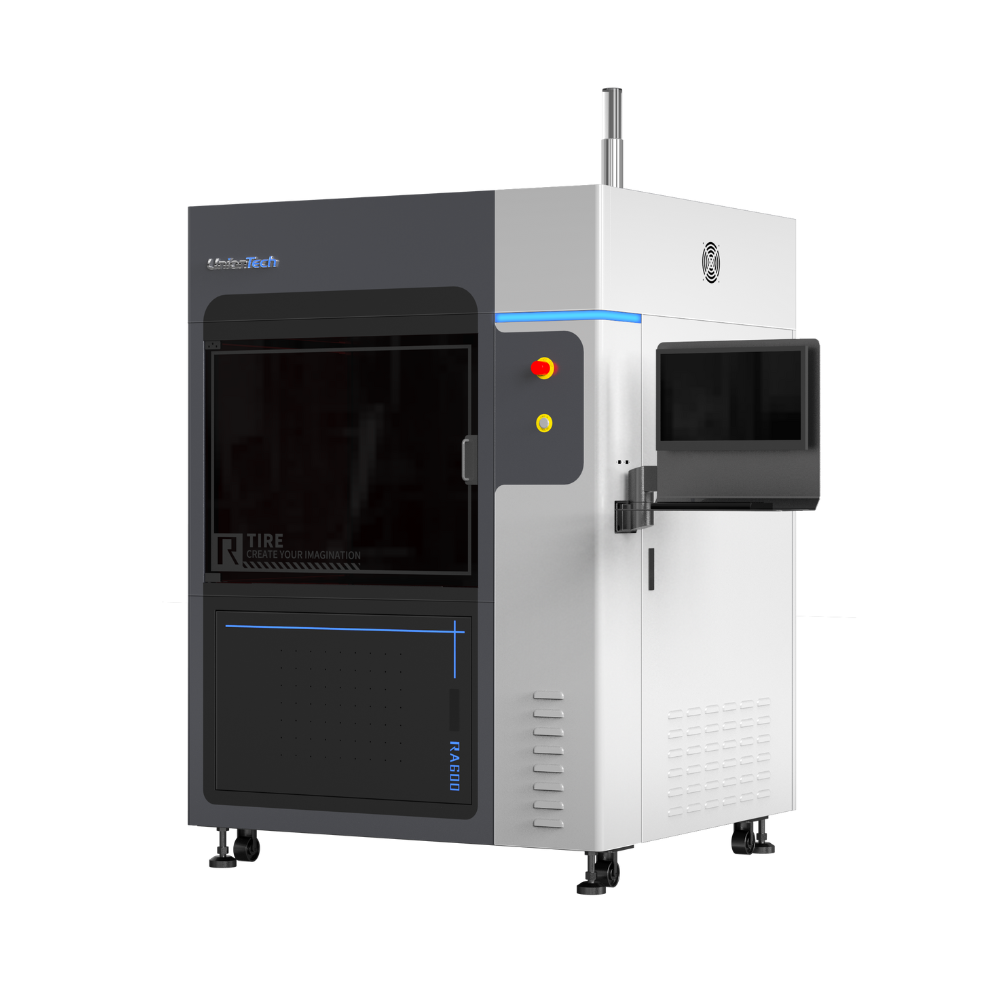

RA600

Tire Mold Patterns in Hours

RA600, designed for tire molds, ensures precise pattern production and boosts productivity while lowering costs. Using 3D printing for tire mold production shortens lead times and reduces labor costs, achieving a precision of ±0.10 mm for complex designs.