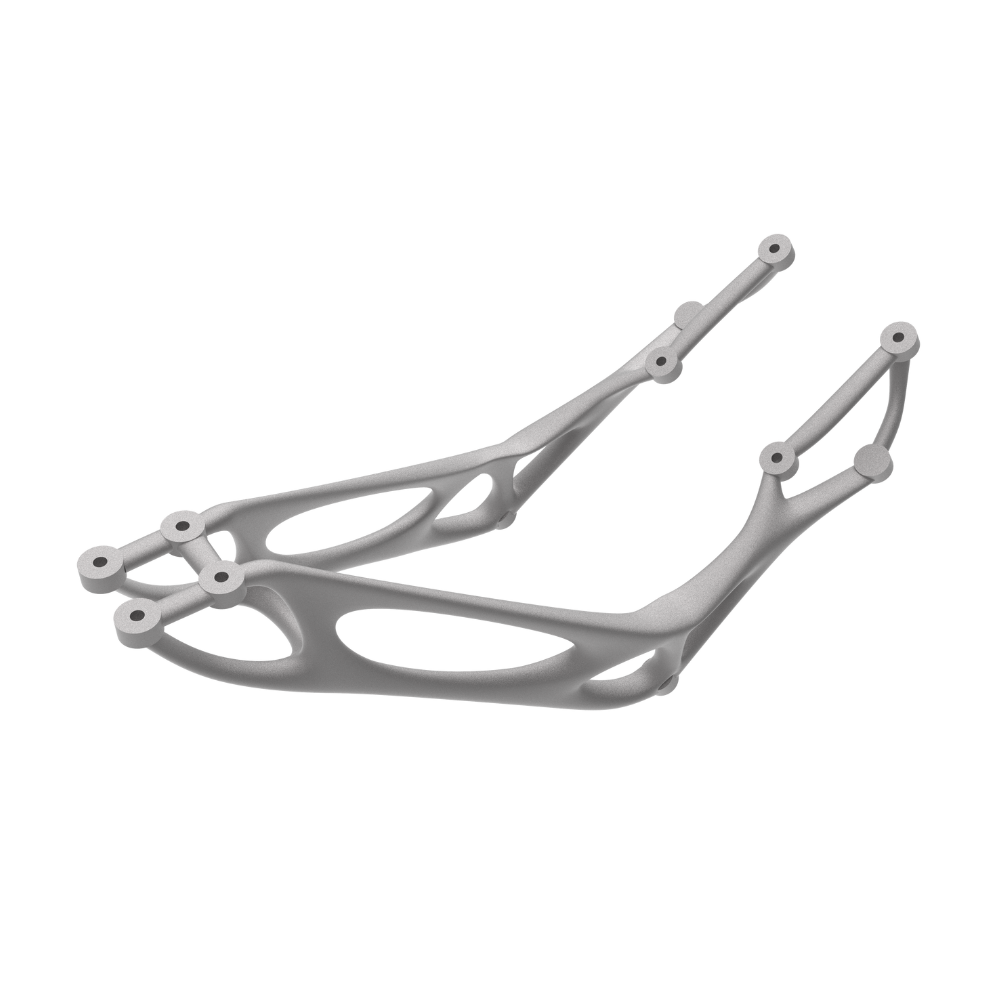

HBD TA15 Titanium Alloy

Lightweight, High-Temperature Titanium Alloy

HBD TA15 titanium alloy is a nearly α-type alloy with low density and high specific strength, maintaining its strength even at elevated temperatures up to 500 °C. It is commonly used in aerospace applications due to its durability and performance in high-temperature environments.